Box Erecting for Consumer Goods

- Semi-Automatic Erectors: These systems require some manual intervention, such as feeding flat cardboard blanks into the machine, but automate the majority of the erecting process, including folding and sealing.

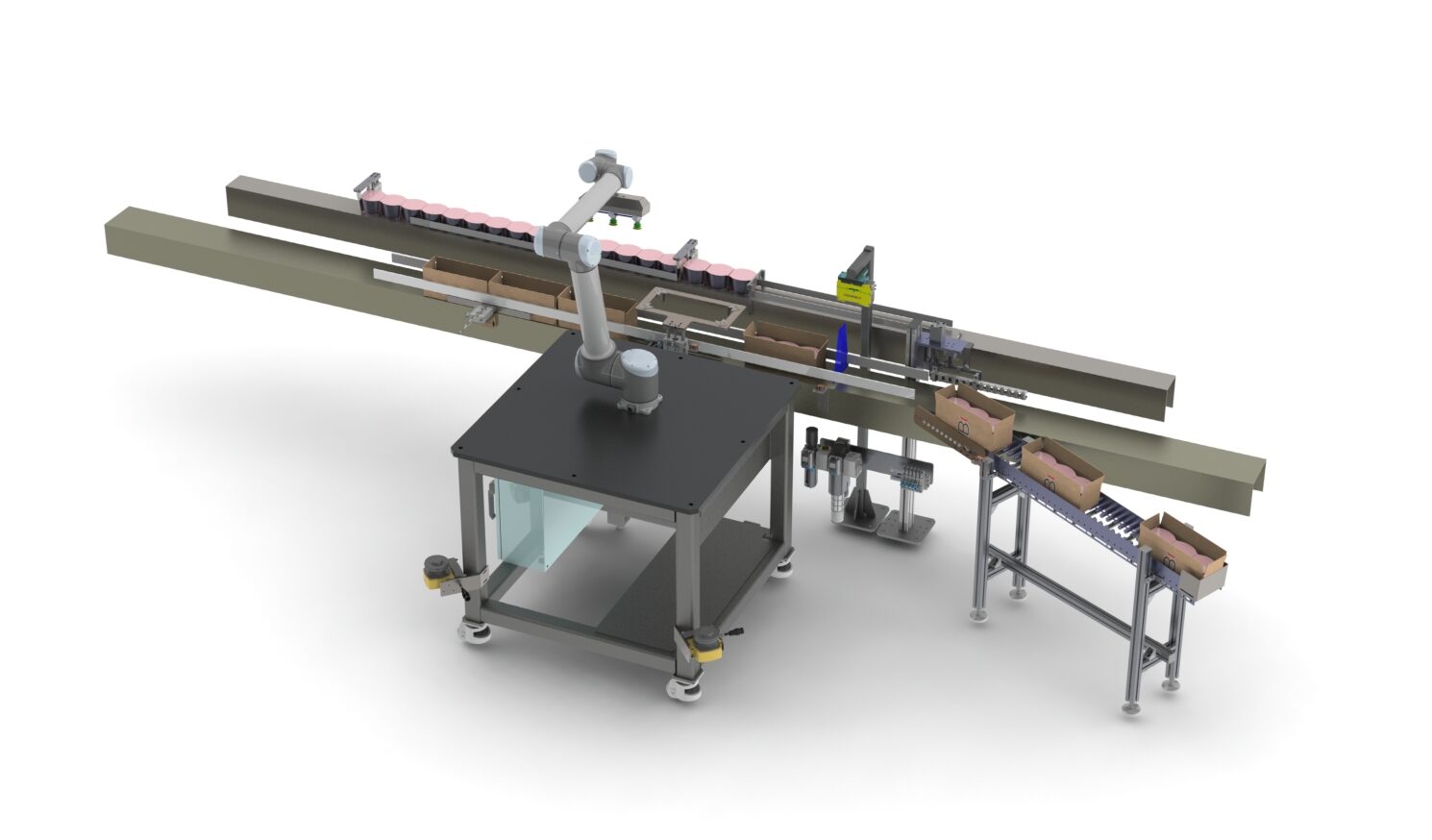

- Fully Automatic Erectors: These systems are fully automated and can handle the entire box erecting process from start to finish without the need for manual intervention. They often feature robotic arms or mechanical devices that precisely fold and seal boxes at high speeds.

- Case Formers: Capable in forming shipping cases from flat cardboard blanks, ensuring that the boxes are properly folded and sealed before being filled with products.

Benefits of Automated Box Erecting

- Increased Efficiency: Automated box erecting systems can significantly increase the speed and throughput of the packaging process compared to manual methods.

- Consistency and Accuracy: Automation reduces the risk of errors and inconsistencies in box assembly, leading to higher-quality packaging.

- Labor Savings: By automating the box erecting process, reduce reliance on manual labor and reallocate resources to more value-added activities.

- Space Optimization: Optimize the arrangement of boxes on packaging lines to maximize space utilization and minimize waste.

Partner with Us for Superior Box Erecting Solutions

Overall, box erecting is a critical component of the consumer goods packaging process, and partnering with Rebel Automated Systems will provide an efficient and reliable box assembly to meet you packaging needs.

Contact Us Today

Ready to boost your packaging efficiency with cutting-edge automated box erecting technology? We can help you streamline your operations and enhance your packaging precision and speed.